A major aluminum extrusion system installed in Los Angeles recently required a technological optimization intervention, with the aim of improving sampling operations, reducing downtime and increasing overall line performance.

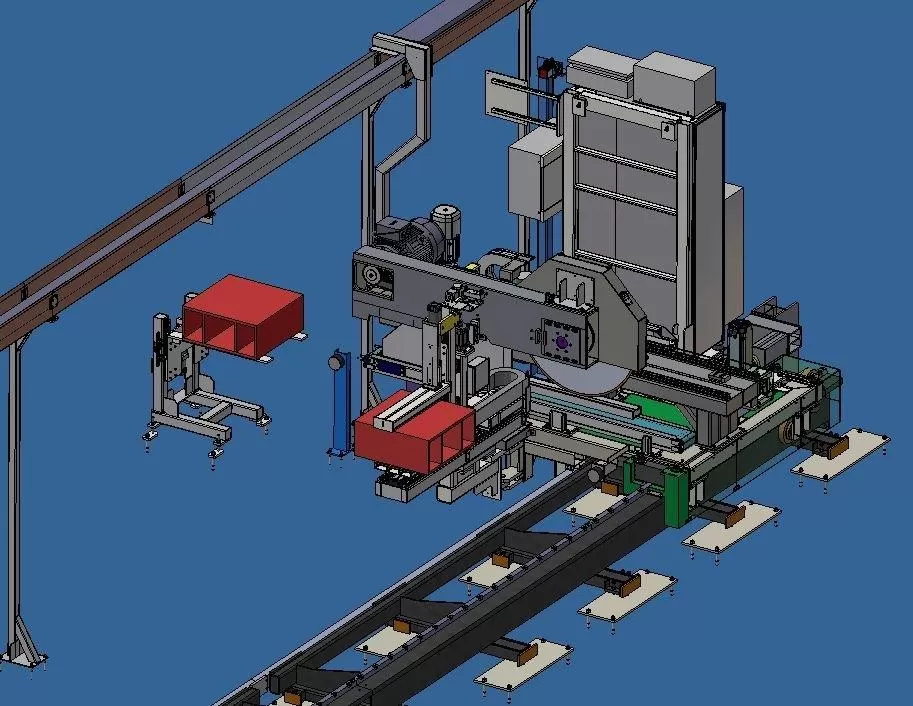

The system, which was started by HS Automation in 2020, was already equipped with a mobile hot saw for fly and at-standstill cutting. The customer required the integration of a second mobile sample saw, specifically dedicated to picking during fly cutting, without compromising already limited spaces and maintaining the efficiency of the production cycle.

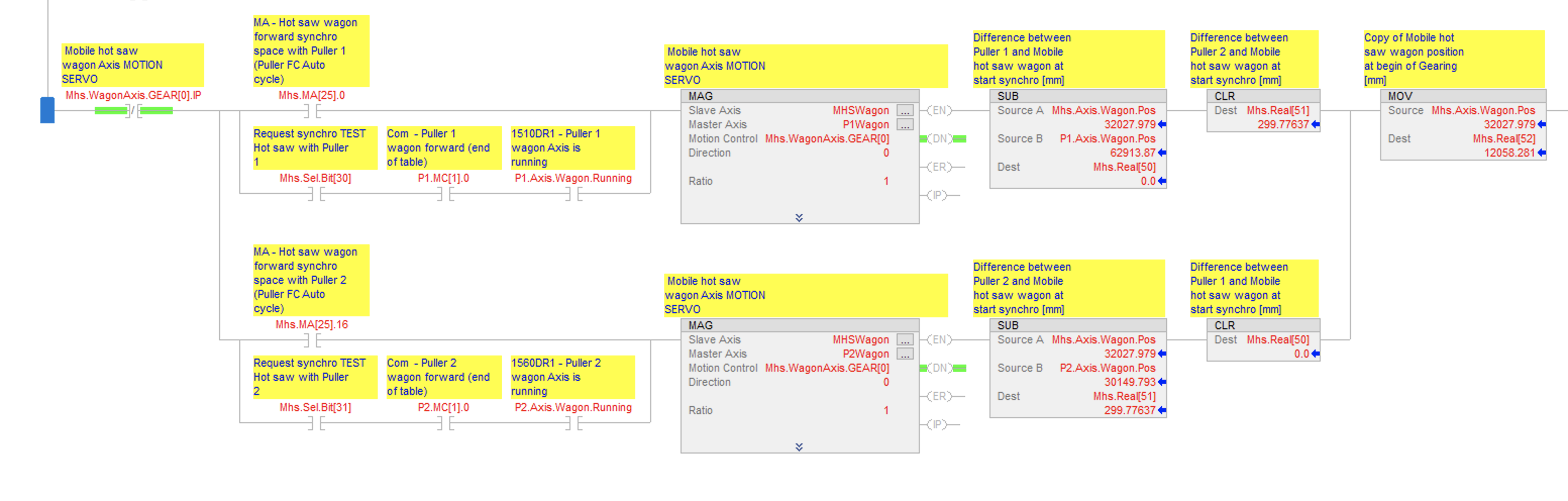

The solution required an advanced synchronization approach, with simultaneous control of four axes: two pullers and two hot saws. To ensure smooth movements without critical mechanical stress, we used the Rockwell 1756-L82ES with native motion management, in combination with the Kinetix system.

Mechanically, the cutting rollers section had to be lengthened. This has increased the maximum extrusion speed from 45 m/min to 55 m/min, which has a direct impact on productivity.

Furthermore, all cutting rollers have been made independent by the addition of pneumatic solenoid valves to increase flexibility in cutting positions. The work was completed by the installation of an additional cooling fan to support the new operating conditions.

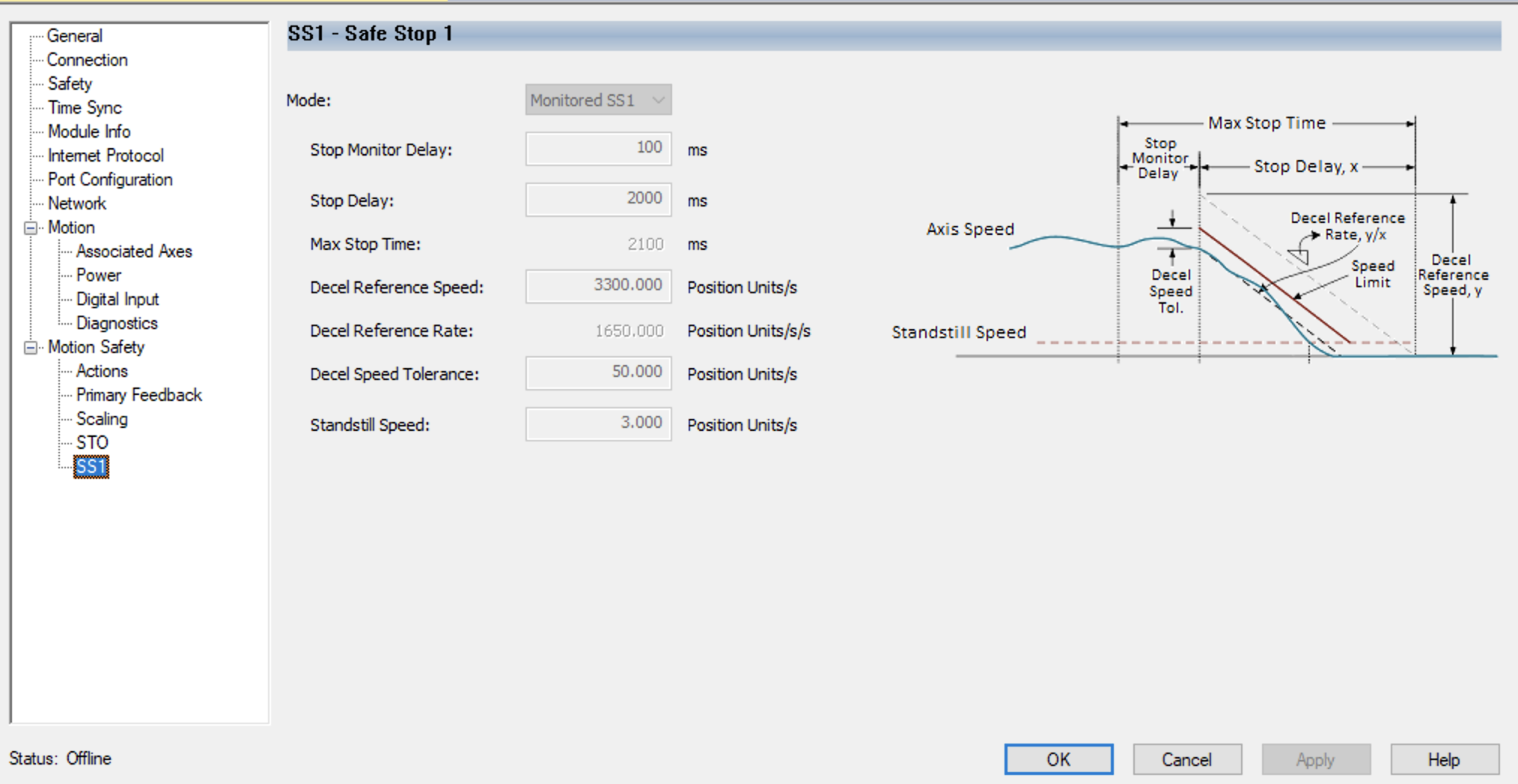

Finally, a complete adaptation of the safety systems was carried out, in line with international regulations and with the "Safety first" philosophy that guides every job designed by HS Automation.

This project demonstrates our ability to work on complex existing systems, providing high-tech solutions that are quick to implement and perfectly integrated into the production environment.