Software

technical specifications provided by the customer. Thanks to a team of highly qualified engineers, we are able to create customized software solutions for the control and management of systems and machinery, ensuring high performance, safety and maximum operational efficiency.

With two decades of experience, we are experts in extrusion and forging processes within the field of metallurgy. This expertise allows us to tackle the most complex challenges in the field of automation, offering robust and reliable solutions for every phase of the production process.

Our approach always begins with a thorough analysis of the documentation provided by the client, which may include electrical, pneumatic, and hydraulic diagrams, plant layouts, and process flowcharts. This data is essential for developing software that is seamlessly integrated with the plant and capable of meeting all production needs.

We handle the complete software design and programming, taking care of every detail to ensure precise and efficient control of the entire system. From managing automation logic to advanced production process supervision, our goal is to provide reliable, scalable, and easy-to-maintain software.

Skills and technologies

1. Software for HMI and SCADA

We create intuitive and high-performance Human Machine Interfaces (HMI), designed to ensure maximum control and monitoring of industrial processes. We specialize in the development of Rockwell and Siemens HMI panels, as well as the programming of third-party SCADA software, for effective, real-time system supervision.

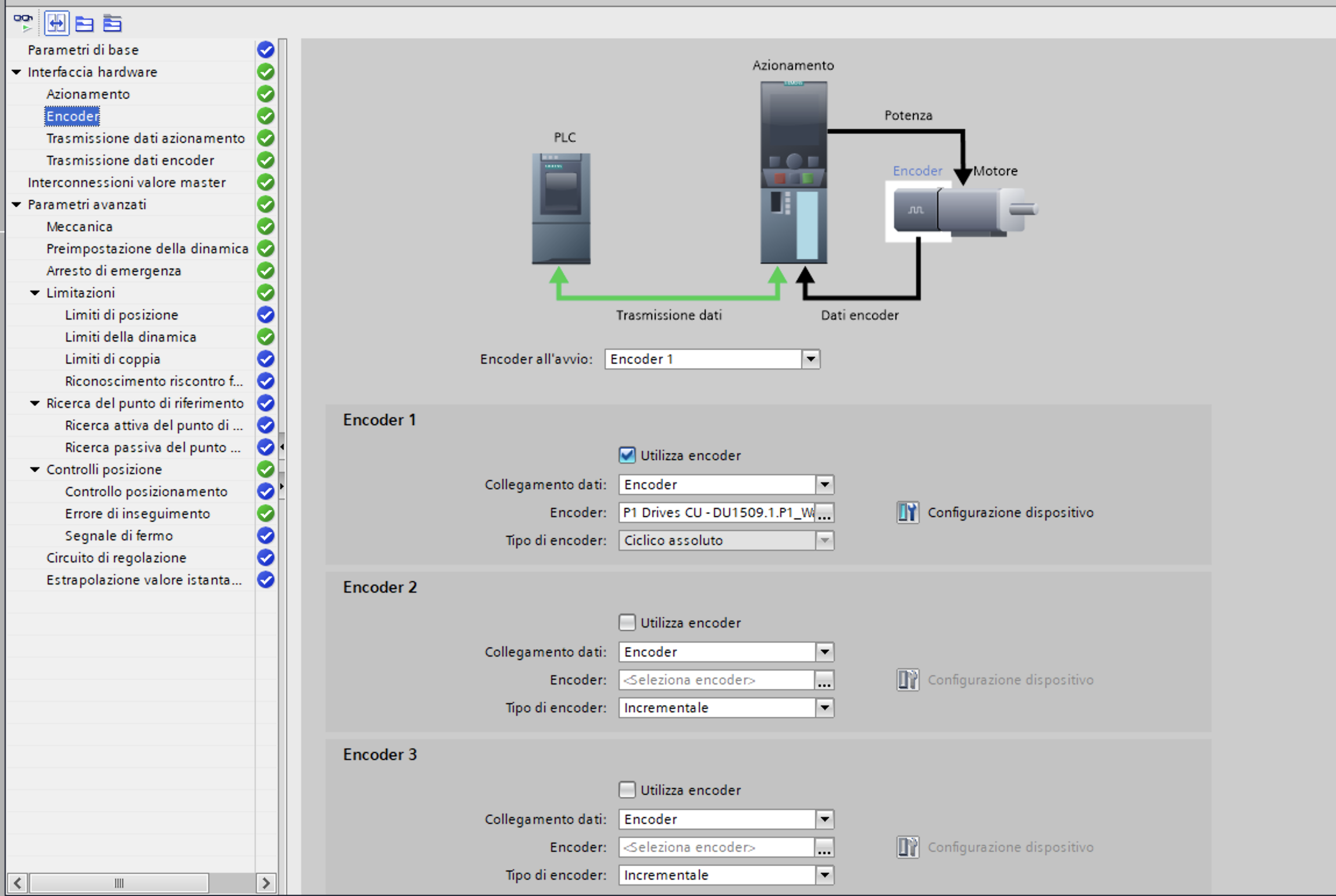

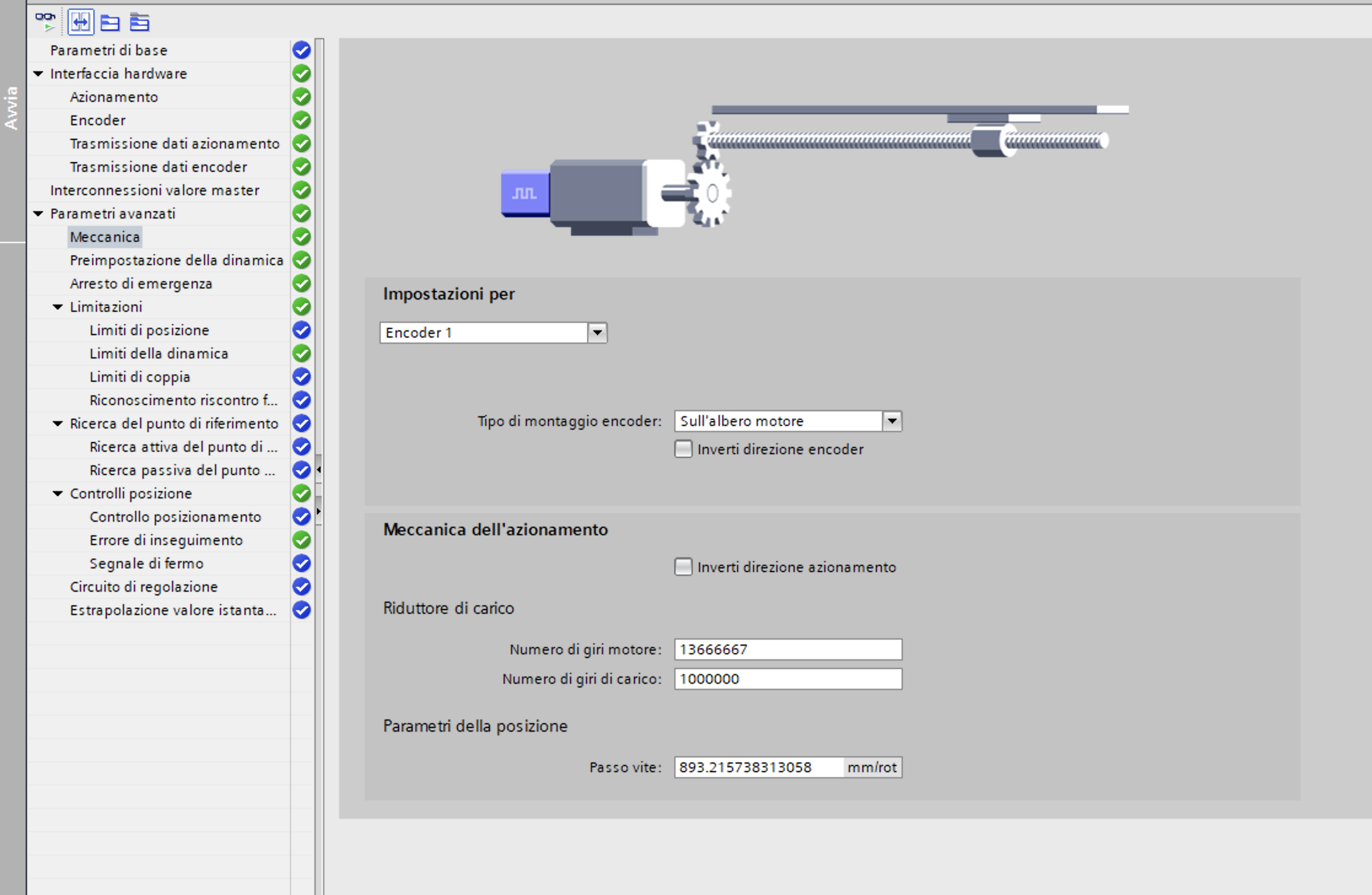

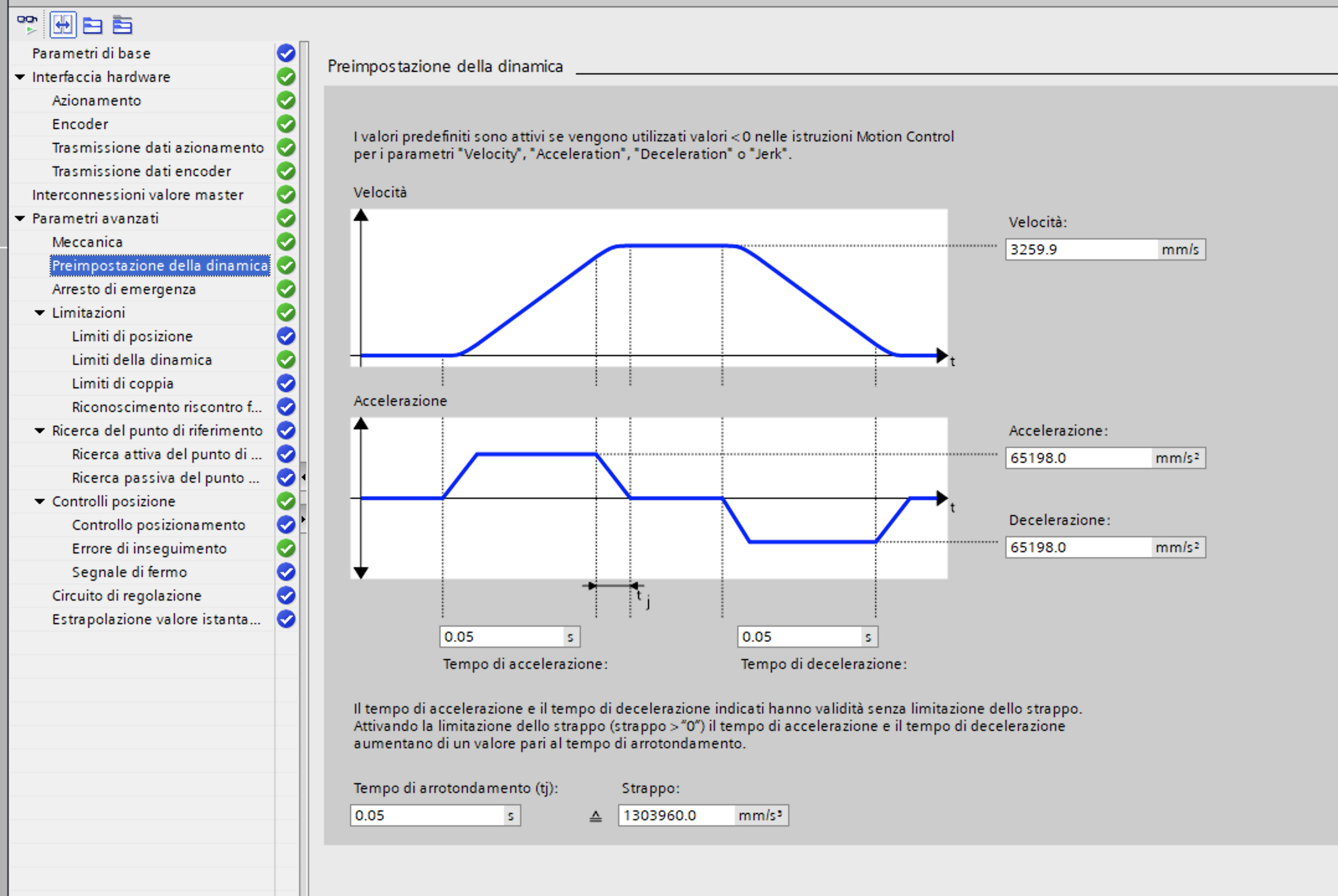

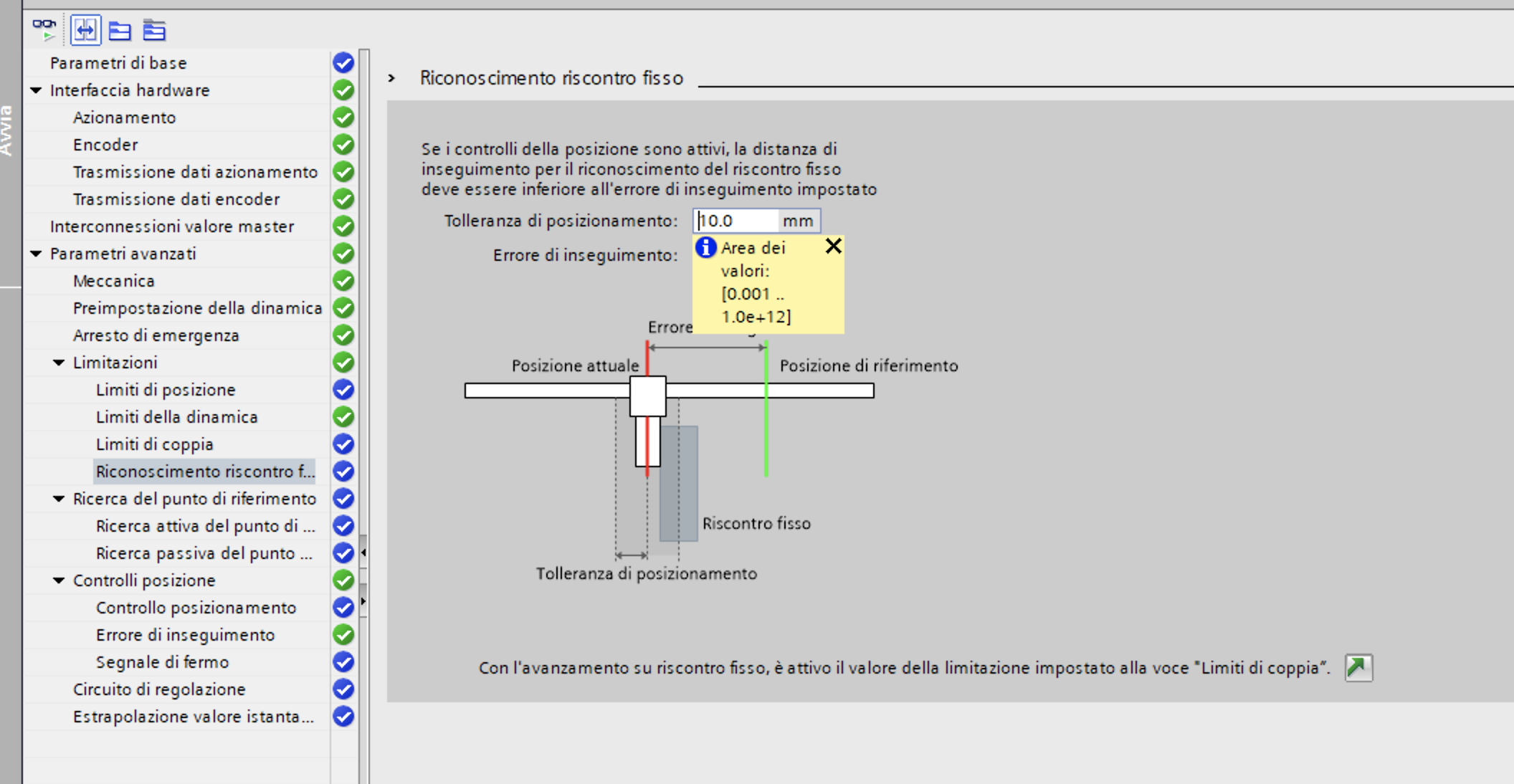

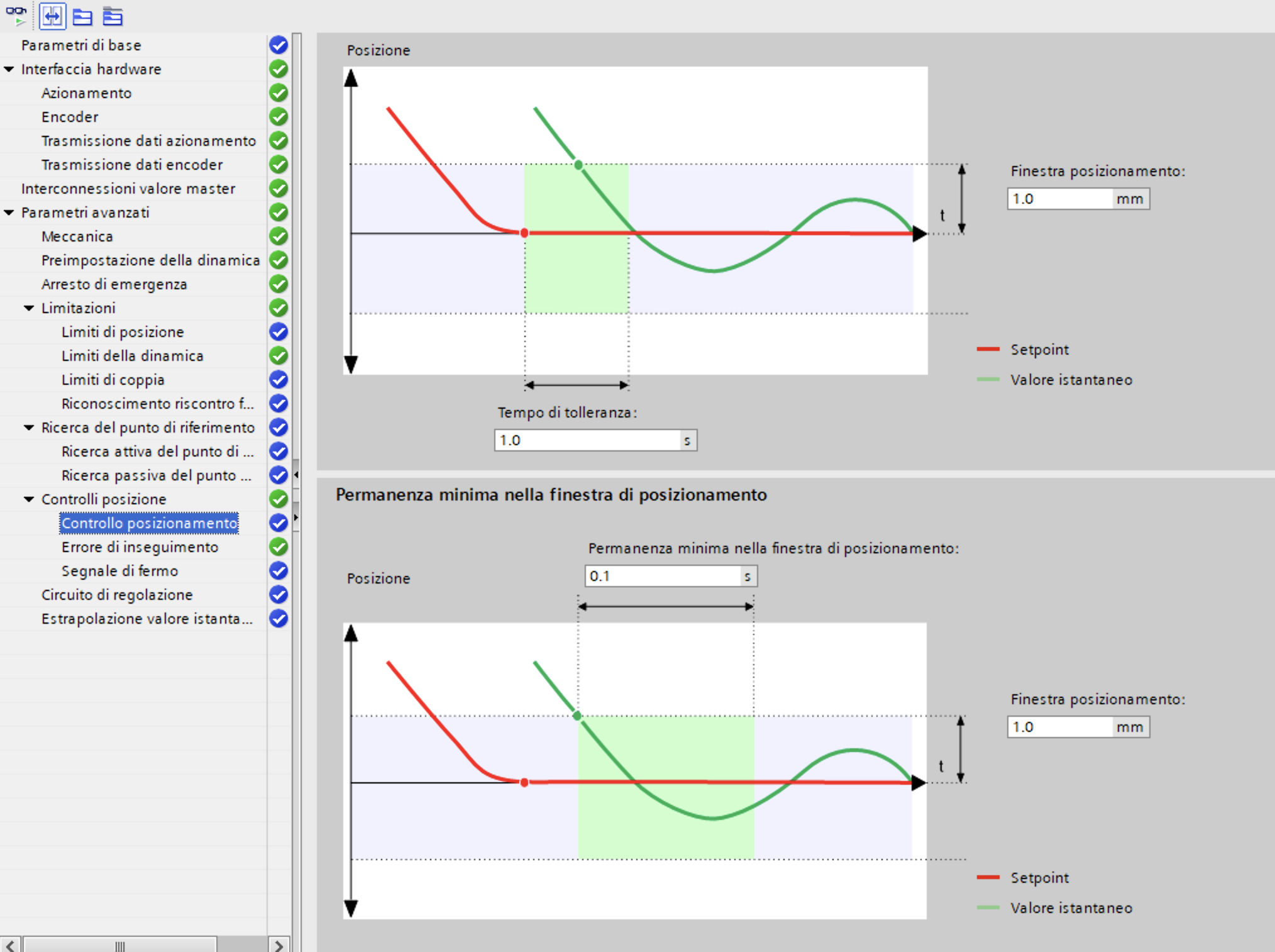

2. Drive and Motion Control Programming

We have advanced skills in managing complex drives of all major brands on the market. Furthermore, we develop software dedicated to the management of motion components, exploiting the advanced features of the latest generation CPUs from Rockwell and Siemens. This allows us to ensure precise and synchronized movements, optimizing the system's performance.

3. Software Revamping and Optimization of Existing Systems

We do not only deal with new developments, but also with software revamping, i.e. the updating and restructuring of existing programs. This process allows to improve the efficiency and safety of the systems, adapting them to the latest technologies and regulations.

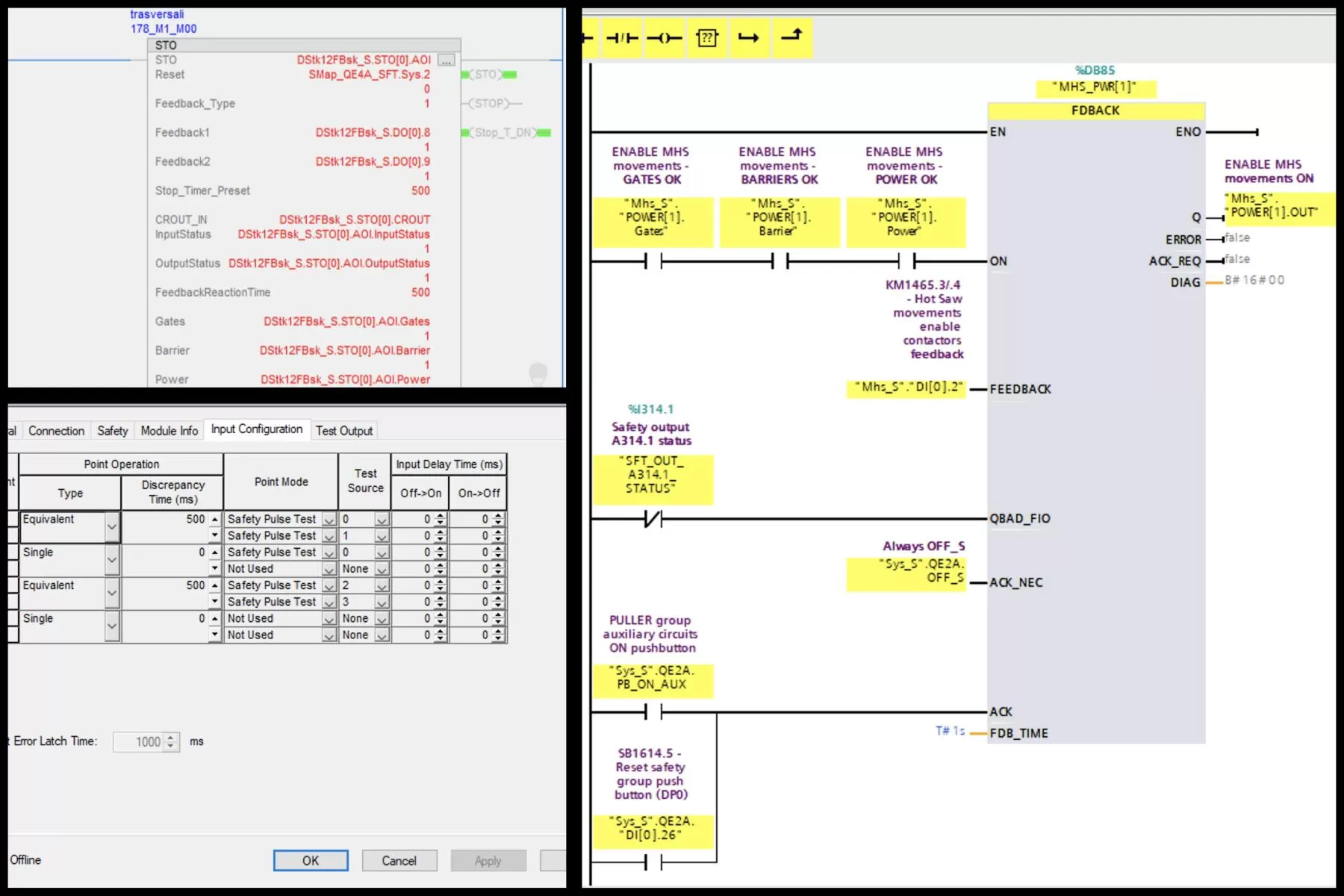

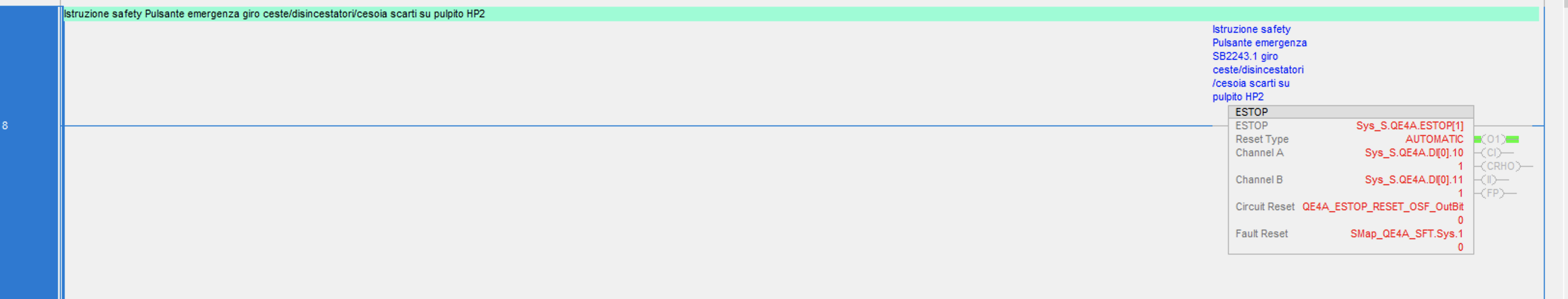

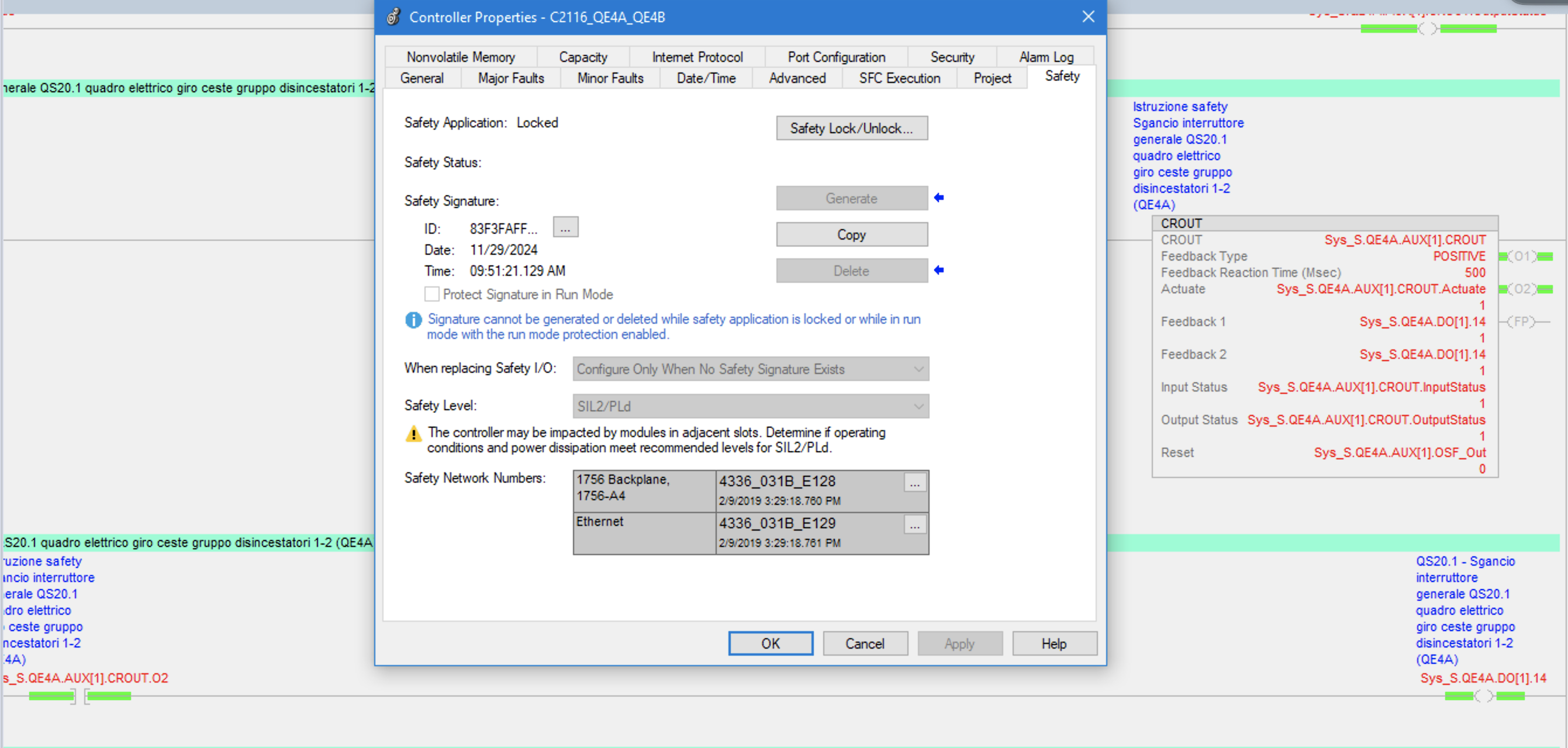

4. Software Safety and Human-Machine Safety

Safety is a fundamental aspect of industrial automation. We develop safety software, taking advantage of fail-safe features of the most advanced CPUs, ensuring compliance with current regulations on human-machine safety. Our goal is to ensure reliable and certified systems, minimizing the risk of failures or malfunctions.

A reliable technology partner

Relying on HS Automation means choosing a partner with high technical expertise, capable of developing cutting-edge automation software, tailored for each system. Our team works with precision and attention to detail, ensuring innovative and high-performance solutions for the metallurgical industry and other sectors of industrial automation.