For HSA, safety is not an option it’s the principle guiding every project and every line of code. All our systems are developed with rigorous attention to human protection and regulatory compliance.

Pioneers in PLC Safety

We were among the first to transition from traditional safety relays to Safety CPUs, developing dedicated software structured according to current regulations. This approach has enabled us to design systems that are more reliable and scalable.

Evolving Technologies, Constant Safety

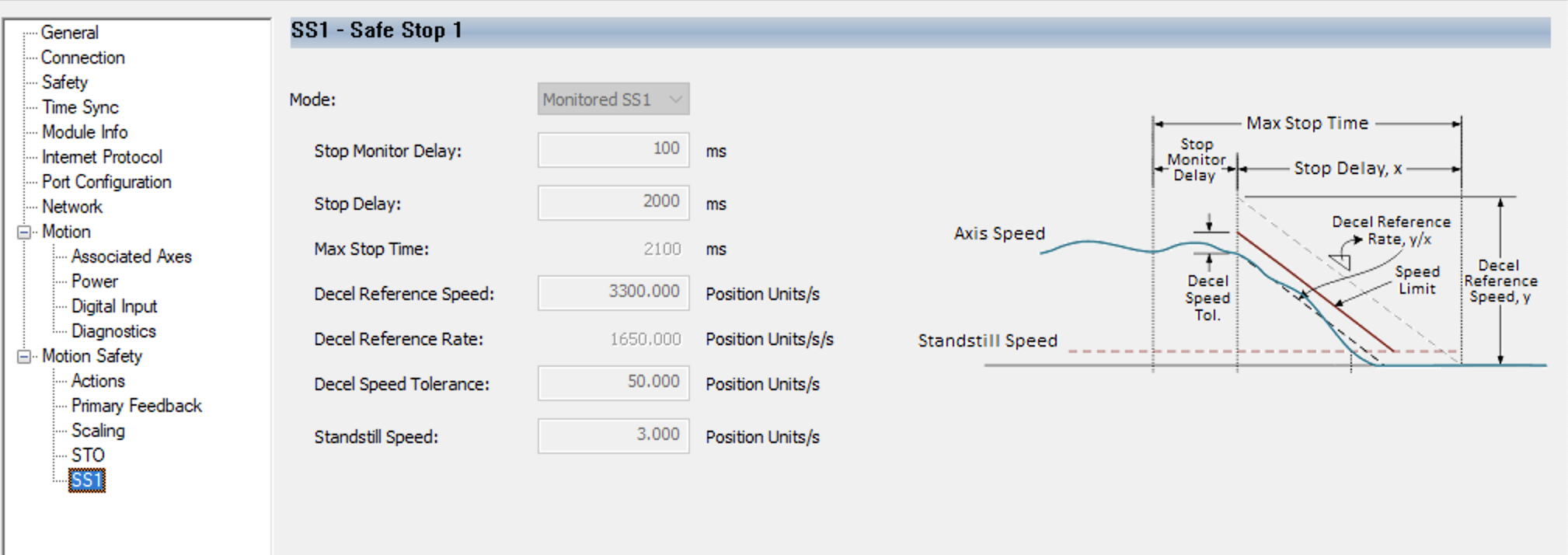

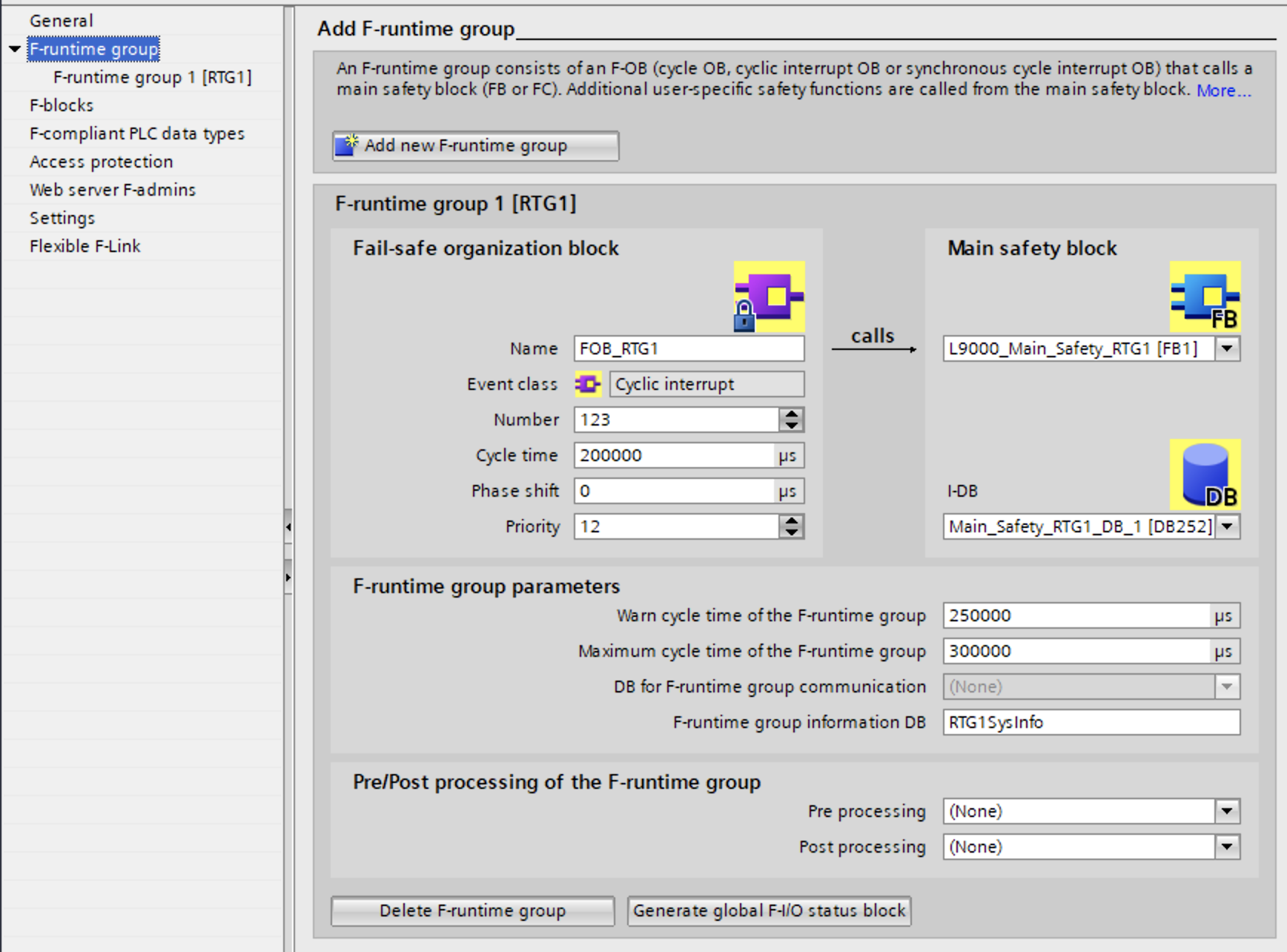

Over the past decade, field devices and sensors (laser barriers, laser scanners, interlocks, etc.) have advanced dramatically. At the same time, PLCs have expanded their safety capabilities. HSA has kept pace with this evolution, creating increasingly sophisticated safety applications with human–machine safety logics designed to reduce risk and increase system availability.

Method and Compliance

Every project begins with a risk analysis and results in clear, traceable, and verified safety code written to fully comply with applicable standards. For us, programming a PLC always includes a carefully planned and documented safety component.

Multi-Brand Expertise

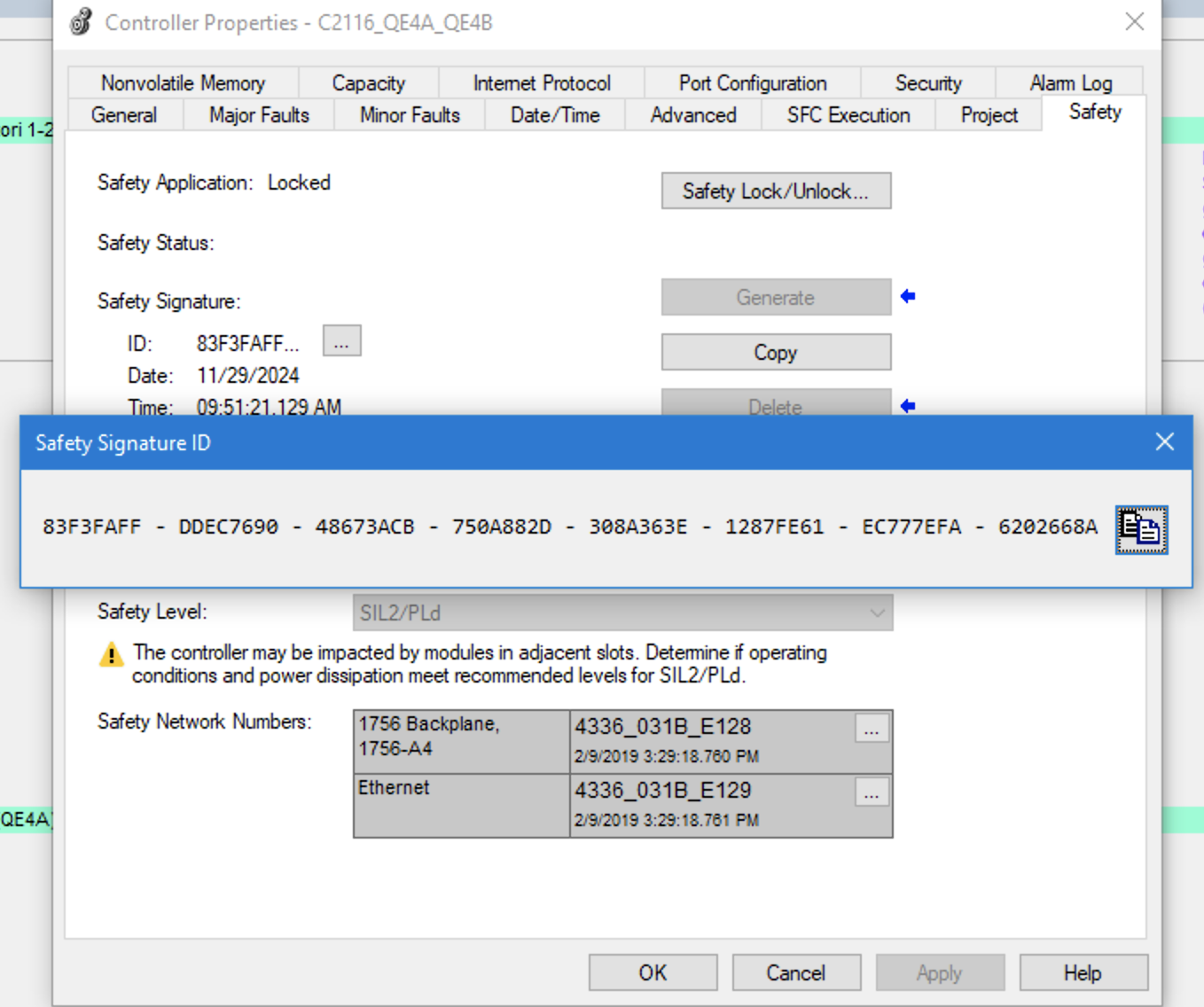

We have extensive experience programming the major brands on the market, including Rockwell and Siemens, ensuring seamless integration with sensors and actuators from various manufacturers.

Commissioning with Guaranteed Integrity

We don’t leave the site until the safety software has been tested, validated, and secured. We set safety passwords and safety signatures to prevent unauthorized modifications and preserve system integrity over time.