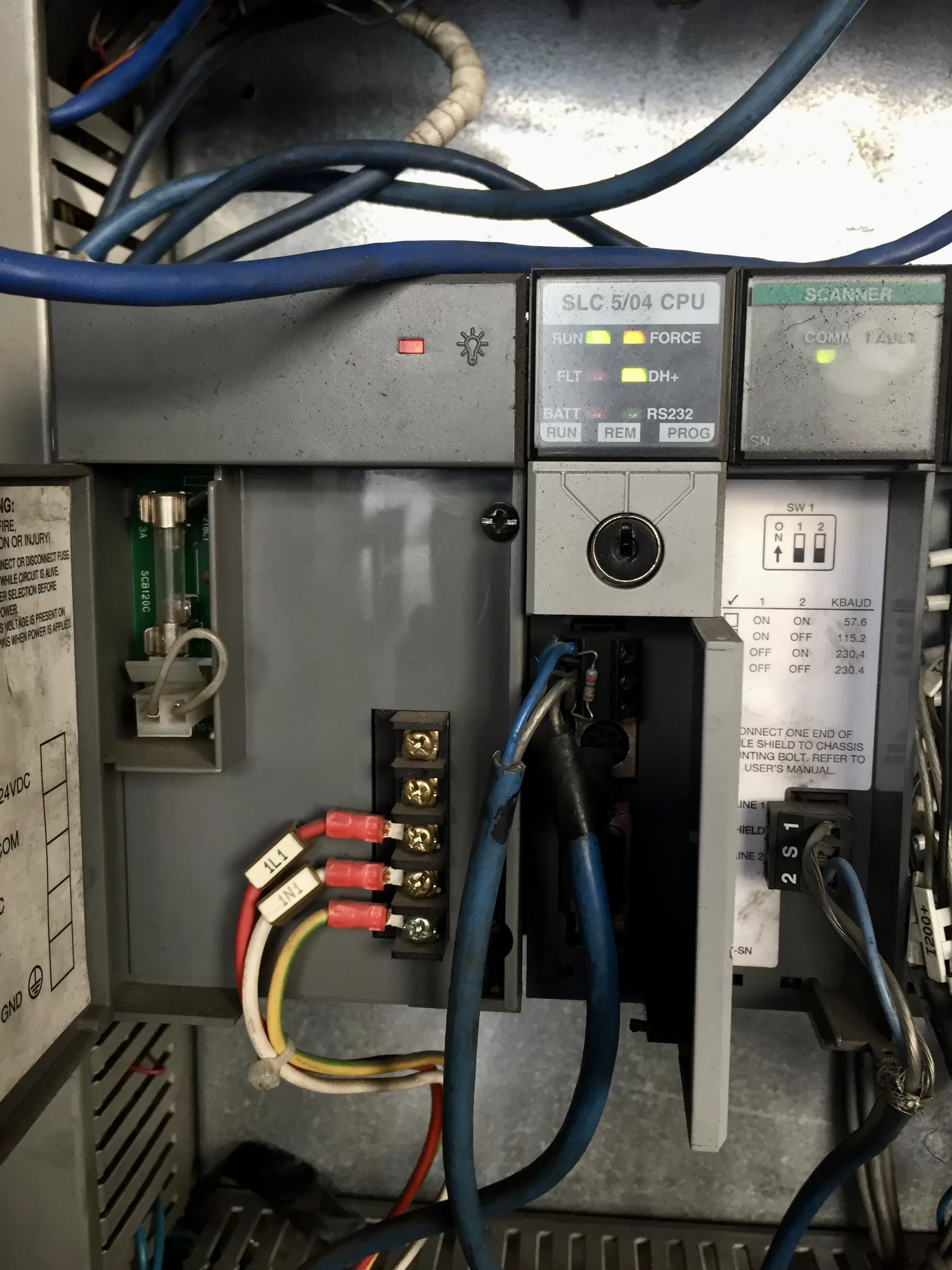

The term retrofit refers to the set of technological upgrades applied to machinery or systems that are already in operation. In the software domain, it involves replacing or rewriting outdated control programs with more advanced versions capable of communicating with modern devices, sensors, and supervisory systems.

Through retrofit activities, it is possible to extend a plant’s service life, increase production efficiency, and reduce maintenance costs — all without the need for a complete overhaul.

Software Revamping: Updating to Evolve

Software revamping is a process of restructuring and optimization that allows companies to:

- Enhance plant safety, aligning systems with the latest industry standards and regulations;

- Optimize control system performance through advanced automation logics and modern user interfaces;

- Integrate new technologies such as IoT, advanced SCADA systems, and predictive analytics based on real-time data;

- Simplify maintenance with clearer, modular, and well-documented software architectures.

The Added Value of HS Automation’s Expertise

Leveraging our extensive experience in industrial automation and strong partnerships with leading technology providers such as Rockwell Automation, Siemens, Rittal, and Cubic, we deliver tailor-made revamping and retrofit solutions.

Following an in-depth analysis of the plant and its critical points, our engineers design customized upgrades that enable clients to:

- Restore full operational efficiency;

- Increase productivity and process accuracy;

- Make their infrastructure fully compatible with Industry 5.0 technologies.

Efficiency, Safety, and Sustainability

Choosing retrofit and software revamping means investing in technological sustainability. Updating existing systems minimizes waste, reduces environmental impact, and enhances the value of existing technical assets — turning modernization into a concrete step toward greater energy efficiency and operational continuity.