Hardware

Each panel is a strategic project: the timescale is assured, as well as total control and certified quality. With over 25 years of experience in industrial automation, HS Automation specializes in the construction of low-voltage electrical panels for every production area, in Italy and worldwide.

We design our panels in-house, but we can also operate on customer-supplied specifications, guaranteeing in both cases short production time thanks to process optimization and the use of cutting-edge technologies such as the Perforex milling system, which drastically reduces the processing time of the plates and electrical carpentry of our products.

1. In-house production, full control.

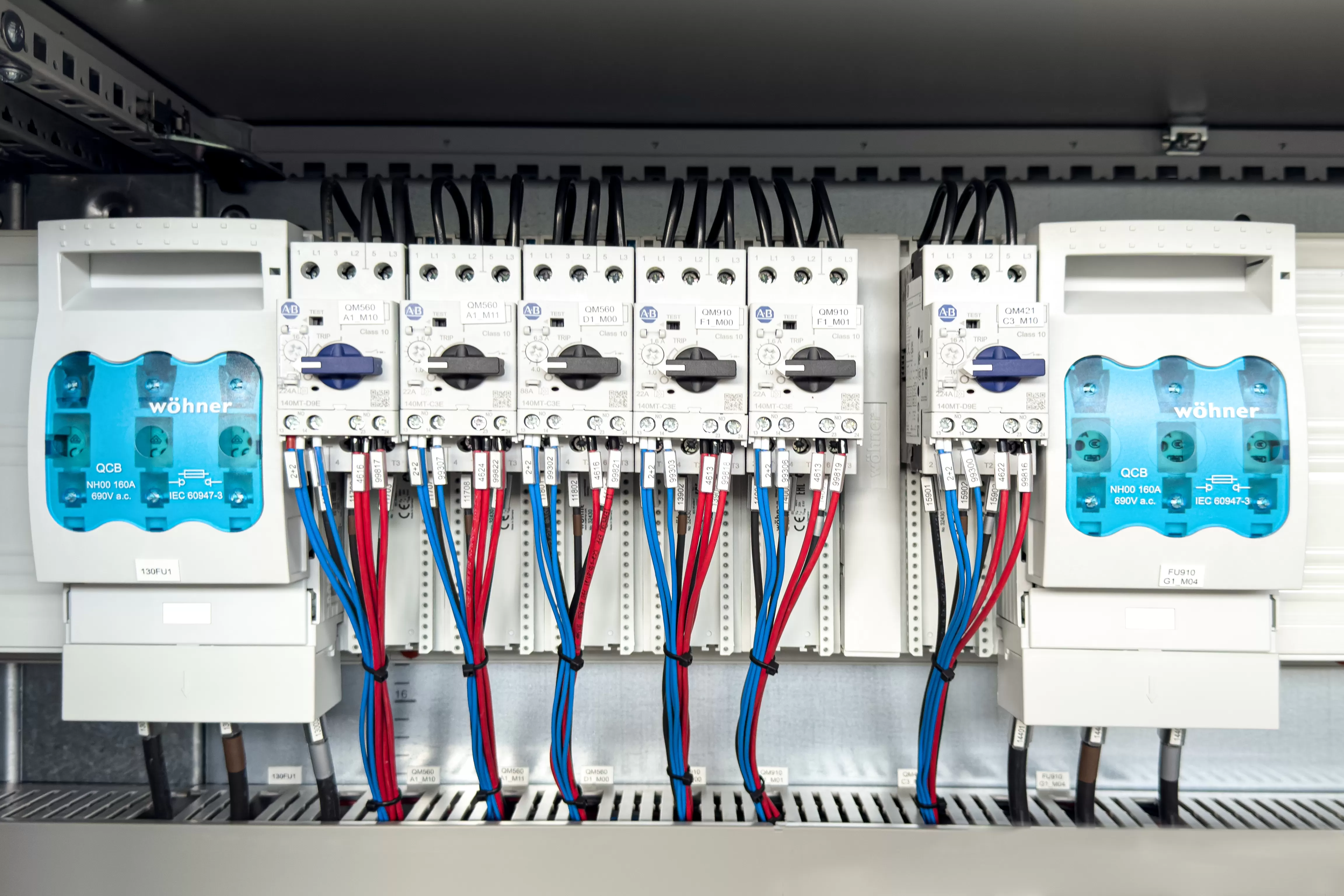

Every panel is made in-house in our factory: from plate machining and drilling, to milling of electrical carpentry, to wiring and final testing. All activities are managed under one roof, ensuring maximum control, traceability and quality. In exceptional cases, we use selected external suppliers: historical, reliable partners that are perfectly aligned to our quality standards.

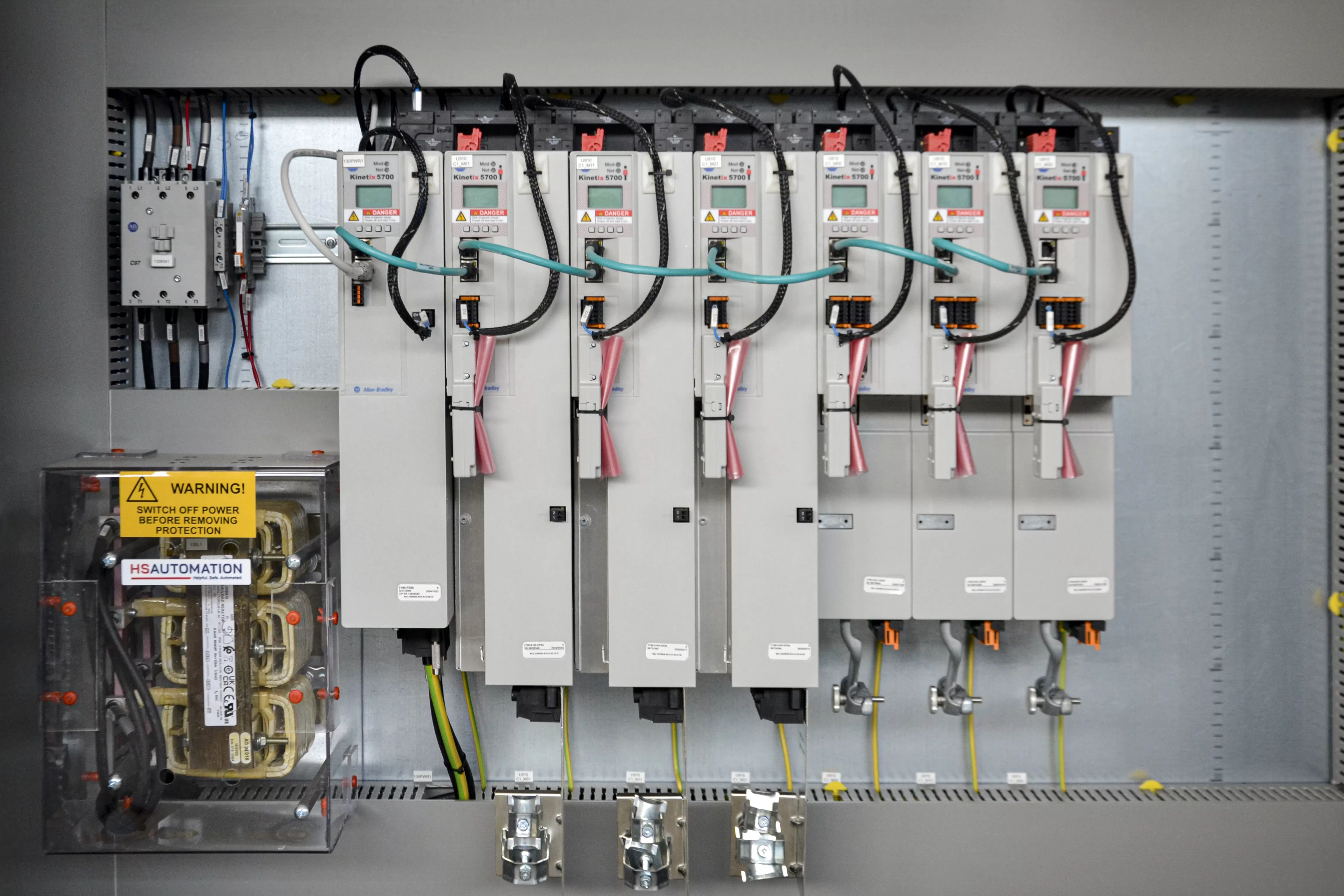

2. Certified quality, ready for every destination.

Each panel is tested in-house, both in the power and logic parts, before delivery. We are structured to create panels for any international market, with full management of the required certifications (e.g. CE, UL, CSA) with particular experience in the North American market.

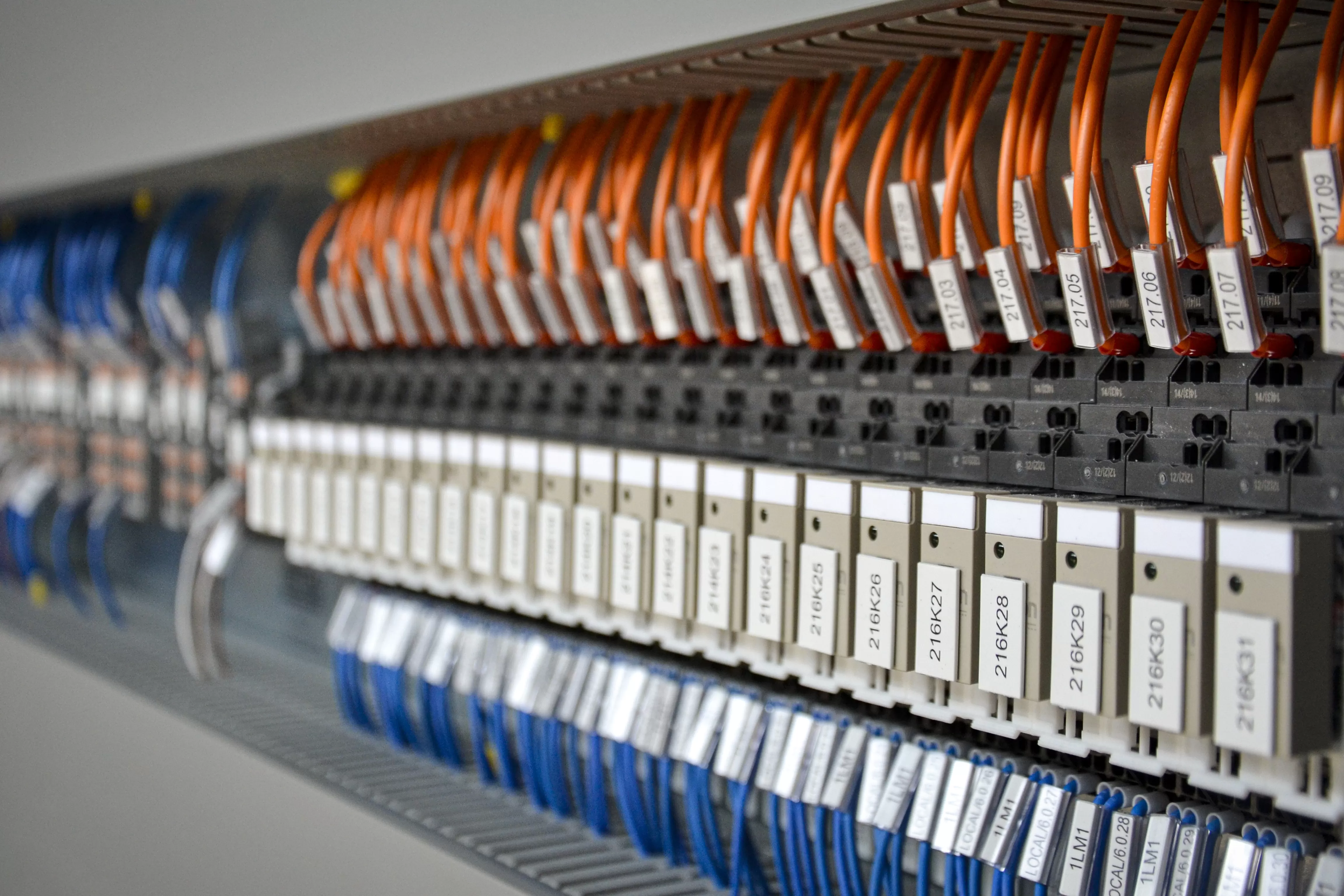

3. High-end materials, professional management.

We only use components from primary brands such as Rockwell, Siemens, Rittal, ABB, Schneider Electric.

ELECTRICAL DESIGN

Electrical design represents a crucial phase in the construction of electrical panels for industrial automation. At HS Automation, we use the latest version of the industry-leading Eplan CAD software to develop highly efficient solutions that meet the highest quality standards.

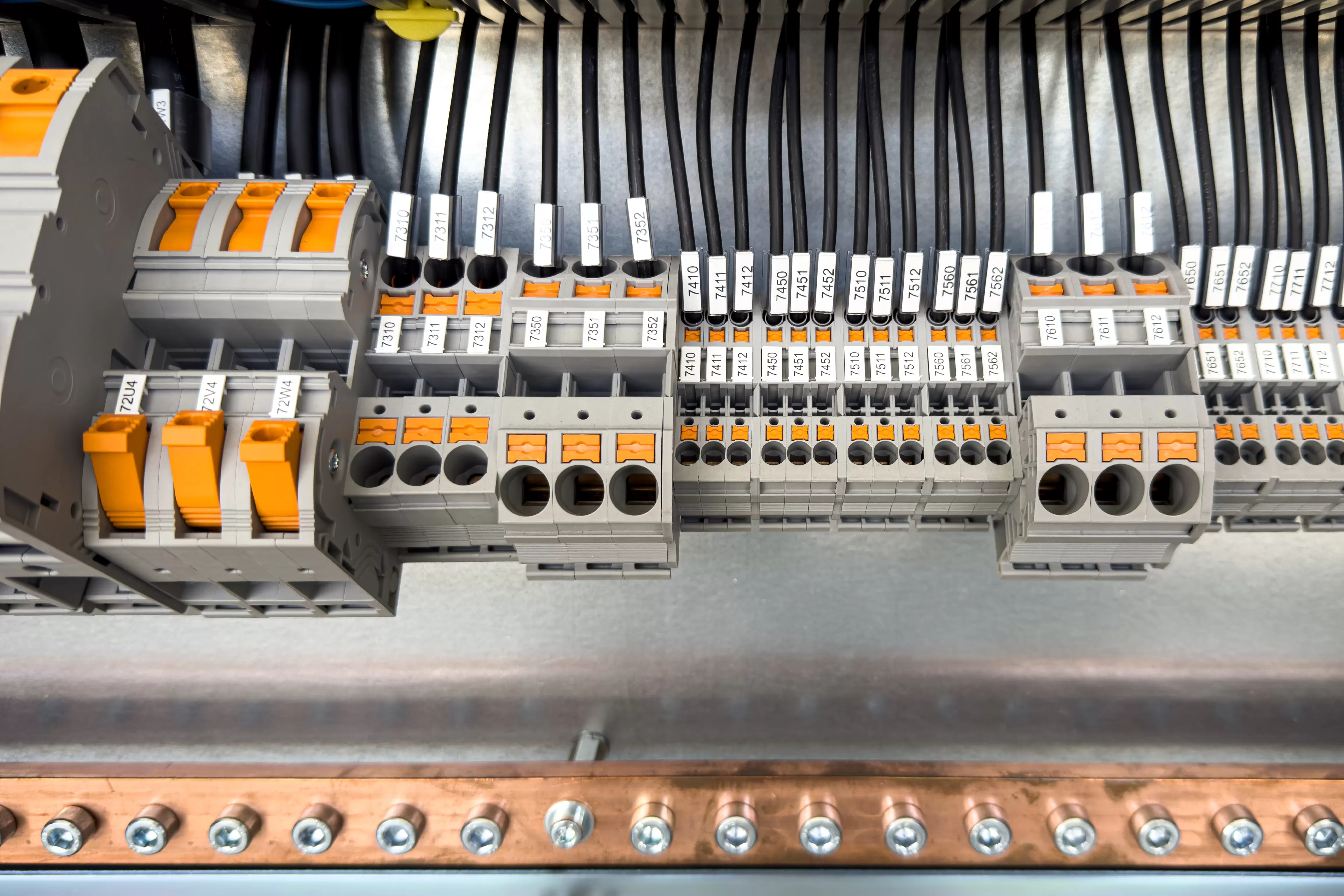

The design process starts with the drafting of the single-line diagram, which provides an overall view of the system, and ends with the automated generation of detailed electrical diagrams, cable lists, terminal blocks and component lists. This structured approach ensures an efficient and precise workflow, reducing margins of error and optimizing production times.

Thanks to the advanced use of EPLAN, we make full use of all the software's features to ensure accurate electrical panel design. This includes:

- Optimization of the internal layout, with effective positioning of equipment to ensure accessibility, safety and optimal ventilation.

- Intelligent management of conductor distribution, to avoid interference, reduce cable length and improve overall system reliability.

- Automation of production processes, thanks to the perfect integration between electrical design and CNC machinery dedicated to the processing of copper bars and metal carpentry.

The adoption of a design methodology based on advanced digital tools allows us to offer tailor-made solutions for systems of any size and complexity, ensuring precision, regulatory compliance and maximum operational efficiency.

Relying on HS Automation means choosing a highly qualified partner for the creation of innovative electrical panels, designed with cutting-edge technology and oriented towards maximum reliability over time.

Every job is followed up by a dedicated Project Manager, who coordinates production, manages timelines and keeps the customer up to date on progress. Reliability, precision and attention to detail: For us, every electrical panel is a unique design that deserves the highest level of care from design to delivery.